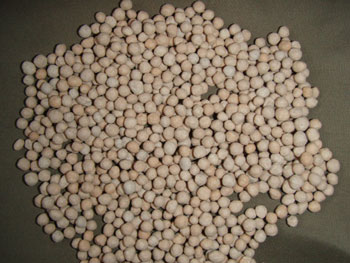

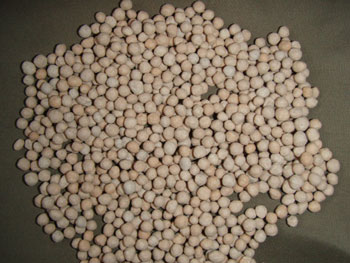

Granulated Single Super Phosphate (GSSP)

Industry Structure and Developments

Granualated Single Super Phosphate (GSSP) Fertilizer industry is the pioneering fertilizer industry in the country and the first GSSP plant is said to have been established by EID Parry in the year 1906. Manufacturing of GSSP is based on perhaps the simplest chemical reaction amongst chemical fertilizer industry. The main raw materials required are rock phosphate and sulphuric acid. GSSP is a straight phosphatic multi-nutrient fertilizer which contains 14.5% water soluble P2O5, 12% sulphur, 21% calcium and some other essential micro nutrients in small proportions. GSSP, which is a poor farmer's fertilizer (price-wise), is an option to optimise the use of phosphatic fertilizers. It also helps to treat sulphur deficiency in soils (40% Indian soil is sulphur deficient) as well for further enhancement of yields at the least cost. In various crops, which require more of sulphur and phosphate like oilseeds, pulses, sugarcane, fruits and vegetables, tea etc, GSSP is an essential fertilizer.

Granualated Single Super Phosphate (GSSP) Fertilizer industry is the pioneering fertilizer industry in the country and the first GSSP plant is said to have been established by EID Parry in the year 1906. Manufacturing of GSSP is based on perhaps the simplest chemical reaction amongst chemical fertilizer industry. The main raw materials required are rock phosphate and sulphuric acid. GSSP is a straight phosphatic multi-nutrient fertilizer which contains 14.5% water soluble P2O5, 12% sulphur, 21% calcium and some other essential micro nutrients in small proportions. GSSP, which is a poor farmer's fertilizer (price-wise), is an option to optimise the use of phosphatic fertilizers. It also helps to treat sulphur deficiency in soils (40% Indian soil is sulphur deficient) as well for further enhancement of yields at the least cost. In various crops, which require more of sulphur and phosphate like oilseeds, pulses, sugarcane, fruits and vegetables, tea etc, GSSP is an essential fertilizer.

Advantages of GSSP Fertilizer

In brief, we can say

Product Specifications

Presently, the products manufactured at our Umarda plant is GSSP:

Manufacturing Process

Process Flow Chart For SSP And GSSP

Granualated Single Super Phosphate (GSSP) Fertilizer industry is the pioneering fertilizer industry in the country and the first GSSP plant is said to have been established by EID Parry in the year 1906. Manufacturing of GSSP is based on perhaps the simplest chemical reaction amongst chemical fertilizer industry. The main raw materials required are rock phosphate and sulphuric acid. GSSP is a straight phosphatic multi-nutrient fertilizer which contains 14.5% water soluble P2O5, 12% sulphur, 21% calcium and some other essential micro nutrients in small proportions. GSSP, which is a poor farmer's fertilizer (price-wise), is an option to optimise the use of phosphatic fertilizers. It also helps to treat sulphur deficiency in soils (40% Indian soil is sulphur deficient) as well for further enhancement of yields at the least cost. In various crops, which require more of sulphur and phosphate like oilseeds, pulses, sugarcane, fruits and vegetables, tea etc, GSSP is an essential fertilizer.

Granualated Single Super Phosphate (GSSP) Fertilizer industry is the pioneering fertilizer industry in the country and the first GSSP plant is said to have been established by EID Parry in the year 1906. Manufacturing of GSSP is based on perhaps the simplest chemical reaction amongst chemical fertilizer industry. The main raw materials required are rock phosphate and sulphuric acid. GSSP is a straight phosphatic multi-nutrient fertilizer which contains 14.5% water soluble P2O5, 12% sulphur, 21% calcium and some other essential micro nutrients in small proportions. GSSP, which is a poor farmer's fertilizer (price-wise), is an option to optimise the use of phosphatic fertilizers. It also helps to treat sulphur deficiency in soils (40% Indian soil is sulphur deficient) as well for further enhancement of yields at the least cost. In various crops, which require more of sulphur and phosphate like oilseeds, pulses, sugarcane, fruits and vegetables, tea etc, GSSP is an essential fertilizer. Advantages of GSSP Fertilizer

- N for Nitrogen {promotes leaf growth and forms proteins and chlorophyll}

- P for Phosphorous {contributes to root, flower and fruit development}

- K for Potassium {contributes to stem and root growth and the synthesis of proteins.

In brief, we can say

- Nitrogen promotes top growth

- Phosphorus promotes good roots

- Potassium benefits the whole plant

Product Specifications

Presently, the products manufactured at our Umarda plant is GSSP:

| Description | Quality | Uses |

| GSSP fertilizer having 14.5% Water soluble P2O5, Minimum 4% Free Phosphoric Acid, Maximum 5% Moisture, Maximum Particle size-Not less than 90 per cent of the material shall pass through 4mm IS sieve and shall be retained on 1 mm IS sieve. Not more than 5 per cent shall pass through 1mm IS sieve. |

As per FCO, 1985 | Fertilizer |

Manufacturing Process

Process Flow Chart For SSP And GSSP